The 7 Rs of Logistics

Seven R’s of Supply Chain Logistics:

What is Supply Chain Logistic?

Logistics comprises the several tasks required to get the right product to the right customers at the right time. More broadly, it also means getting the right quantity of product in the right condition to the right place at the right price.

What are the 7 Rs?

|

| The Seven 7 Rs of Logistics |

|

1. |

Right Product |

|

2. |

Right Customer |

|

3. |

Right Time |

|

4. |

Right Place |

|

5. |

Right Condition |

|

6. |

Right Quantity |

|

7. |

Right Cost |

Right Product:

The first task is to provide the product

according to the details of the order. Now the details can include its size,

its color, etc. The purpose of this is to give the customer the product that

they have asked for.

Right Quantity:

It is also important that the product reaches

the customer in the right quantity. The manager makes sure that the quantity is

supplied according to the customer's requirements. It is important to take care

of this, especially while packing the product. Quantity control requires simplicity

in inventory listing as well as effective selection and packing.

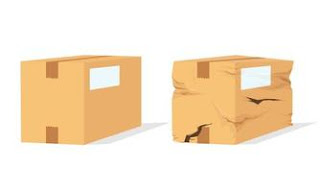

Right Conditions:

From a supply

chain perspective, this means ensuring that the goods reach the customer in a

safe way. Customers always want their products to work well. The quality of the

product remains the same until the goods are delivered. The packaging of

special products is also special. In logistics, it is ensured that the products

are not damaged during the entire process. Therefore, the product should be

inspected for defects or damage before delivery.

Right Place:

Logistics management requires pursuing to promise

delivery. In addition, this is ensured that dispatched items are delivered to

the accurate address. It is also important to get the product to the right

place at the right time and it also improves customer-business relationships. This can be

improved with a location tracking system.

Right Time:

Timing is very important from the point of view

of the customer. If we deliver late, maybe the customer has returned it because

the need for it has ended by that time. It doesn't even depend on the type of

product, whatever the product, the timing of delivery is very

important. Retailers always want products on the shelves to meet demand

and if the demand is not fulfilled at the right time, then it becomes a loss.

Right Customer:

Most of the time, by not paying attention to

customer details, many issues like order blunders and address inaccuracies arise. One of which, for example, if you enter

the wrong address, the delivery will be returned. Which not only starts the

return process but also affects customer service. So, getting the goods to the

right customer increases logistics performance as well as customer satisfaction.

Right Cost:

In order to turn over your inventory frequently

and at a reasonable margin, it is important that your pricing is competitive

for the geographic area and industry. Businesses should keep pricing their

products competitively by looking at market research and trends. Market

research and looking at competing companies is also important.

Conclusion:

In

conclusion, the 7 Rs of supply chain logistics - Right Product, Right Quantity,

Right Condition, Right Place, Right Time, Right Customer, and Right Cost - summarize

the main ideologies necessary for attaining effectiveness, responsiveness, productivity,

and entire accomplishment in contemporary supply chain management. The Seven Rs

assist as a guiding outline for supply chain specialists to direct challenges

such as worldwide complications, market variations, and disruptions. By accurately

addressing each "R," businesses can enhance their processes, improve buyer

satisfaction, and continue competitive in dynamic corporate environment. The

Seven Rs offer an inclusive roadmap for businesses looking for to build robust,

agile, and customer-centric supply chains.

Frequently asked questions (FAQs) about 7 Rs of Supply Chain Logistics:

Q.1: What are the seven Rs of the supply chain logistics?

The seven

Rs of Supply Chain Logistics denote to the important values that guide

effective and efficient supply chain management. They are Right Product, Right

Quantity, Right Condition, Right Place, Right Time, Right Customer, and Right

Cost.

Q.2: Why are the 7 Rs significant in supply chain logistics?

The seven

Rs are important as they offer a complete outline for confirming correctness,

responsiveness, and customer satisfaction all over the supply chain. They support

optimize operations.

Q.3: How does 7 Rs solve supply chain bottlenecks?

The

7 Rs be responsible for a flexible outline that supports supply chain specialists

react to disruptions. By ensuring the right conditions, quantities, and timely

deliveries, businesses can adjust to fluctuations and lessen the effect of

disruptions.

Q.4: Are seven Rs applicable to all businesses?

Yes,

the seven Rs are a multipurpose structure appropriate to numerous businesses.

Whether in manufacturing, retail, or services, these values guide effective

supply chain management.

.png)

.png)

Comments

Post a Comment