WAREHOUSE OPERATIONS AND OPTIMIZATION | Seven value-added warehouse activities

WAREHOUSE OPERATIONS AND OPTIMIZATION | Seven value-added warehouse activities:

In this blog, we will talk

about the warehouse and

its importance. Further, our focus will be on fundamental warehouse activities.

In addition, we will look at how these activities can be carried out to improve

not only the efficiency

of the warehouse but also the efficiency of the entire supply chain and

achieve higher order fulfillment rates.

Hello, I am Rashid and in this blog, we will discuss the various activities of the warehouse. And we will see how these warehousing activities optimize the

entire supply chain process.

Why are warehouses

necessary? For example, the gadget that you currently have in your hand, was

there a need for the warehouse when it was created?

Yes, absolutely. Each part

has its own journey. All the parts used in it must have been stored in some

warehouse at some point. Warehouse is very important in production. Due to the

warehouse, we can store, ship, and further distribute the parts, components,

and products from one single location. Apart from this, it also helps us to

manage our inventory. If there are the right number of locations and

warehouses in your logistics network, it also helps to minimize your transportation costs.

7 Value-added Warehouse Activities:

|

S.no. |

Activities |

|

1. |

Receiving |

|

2. |

Pre-Packaging |

|

3. |

Put-away |

|

4. |

Storing |

|

5. |

Order

Picking |

|

6. |

Packing |

|

7. |

Shipping |

Receiving:

How to measure the cost of

receiving:

How to calculate the receiving efficiency:

- The receiving efficiency can be found by the "Inventory received per hour".

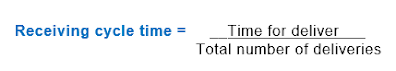

How to calculate receiving cycle time:

- Receiving cycle time can

be found in the formula given below.

Receiving labor productivity:

Method of optimizing the receiving process:

- We can optimize the warehouse receiving process by receiving materials correctly and efficiently. We must prevent the accumulation of different consignments at the receiving docks.

Pre-Packaging:

The second important process of warehousing is the pre-packaging process.

When the consignment is received in bulk quantity, they are packaged later in

smaller quantities or consumer size or combined with other products to form

kits or assortments.

Put away:

The third

process of warehousing is the put-away process. The process in which we

remove the goods from the place where they were received is called the put-away

process. For example, removing goods from the dock. It also includes

transportation or placing of materials in a specific storage area. Finally,

recording and identification of all movement of where the materials are placed.

Basically, it takes into account warehouse capacity and priority.

Put away determines how efficiently our inventories are stocked and how easily

it is accessible.

Measuring the cost of put-away:

- The cost of

this process can be ascertained by the methods given below.

- The accuracy of this process can be ascertained by the methods given below.

Put-away productivity = Stock per warehouse, employee per hour.

Storing:

The fourth and most important process

of warehousing is the storing

process. Storing refers to a process in which materials are

stored in their most appropriate storage area from the time of production to

the time of consumption or putting items under warehouse control. This can

maximize the space utilization within the warehouse.

|

| Warehouse Storage |

You can store more products or

components if you have properly managed your storage area. This allows you to

stock more goods at a time, which helps you to give the best service to your

customers.

Order Picking:

The fifth

process of warehousing is the order-picking process. Order picking is the

warehouse process that refers to collecting the required quantity of exact

products to fulfill one or more customer orders.

By improving this process,

we can control the cost to a great extent because it is the most expensive

process of warehousing. This will not only increase the efficiency of the

warehouse but also increase the efficiency of the entire supply chain.

Packing:

The sixth

process of warehousing is the packing process it is the key process used to

fulfill customer's orders. In the packing process, warehouse officials

consolidate picked items according to a sales order or delivery note and

prepare them for dispatch to a customer. The packing process consists of

choosing appropriate packing materials along with a suitable container to pack

the product. During packing, the package is weighed and its labeling is also

done. During the packing process, full care is taken to ensure that the

goods do not get damaged while leaving the warehouse.

Shipping:

The final stage

of warehouse processes. The process of sending outgoing shipments of products

from the warehouse to the customer is called shipping. This process will be considered

successful only when the delivery item reaches the right customer at the right

quantity, at the right time, at the right address, and in the right condition.

For this, it is necessary to choose the right mode of transportation and a

trusted delivery partner.

Conclusion:

In this blog, we have looked at what activities happen in

the warehouse that increase operational efficiency and overlay the approach for

a more responsive supply chain.

Frequently Asked Questions (FAQs):

Q.1. What are the warehouse activities?

Warehouse activities include many tasks that relate to the

storage, handling and movement of goods within the facility. By optimizing

these processes, you can streamline your warehouse operations, minimize costs

and errors, and achieve higher order fulfillment rates.

Q.2. Why are warehouse activities important?

Warehousing delivers a dominant location for businesses to store, manage, and distribute their goods to end customers. It decreases the costs of obstacles involved in inventory monitoring and management, as well as reducing recruitment requirements and functioning costs.

Q.3. What role does technology play in warehouse activities?

We use difference tools; one of the most important tool we

use for real-time visibility is Warehouse management systems (WMS).

Q.4. What challenges do warehouses face in their operations?

Challenges in warehouse management includes, such as

inventory inaccuracies, unnecessary handling of goods, and changing in customer

demands.

Comments

Post a Comment